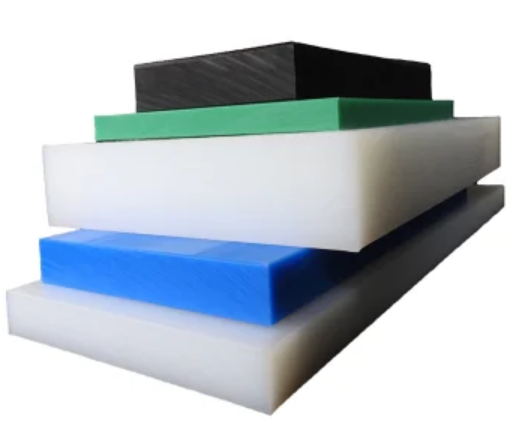

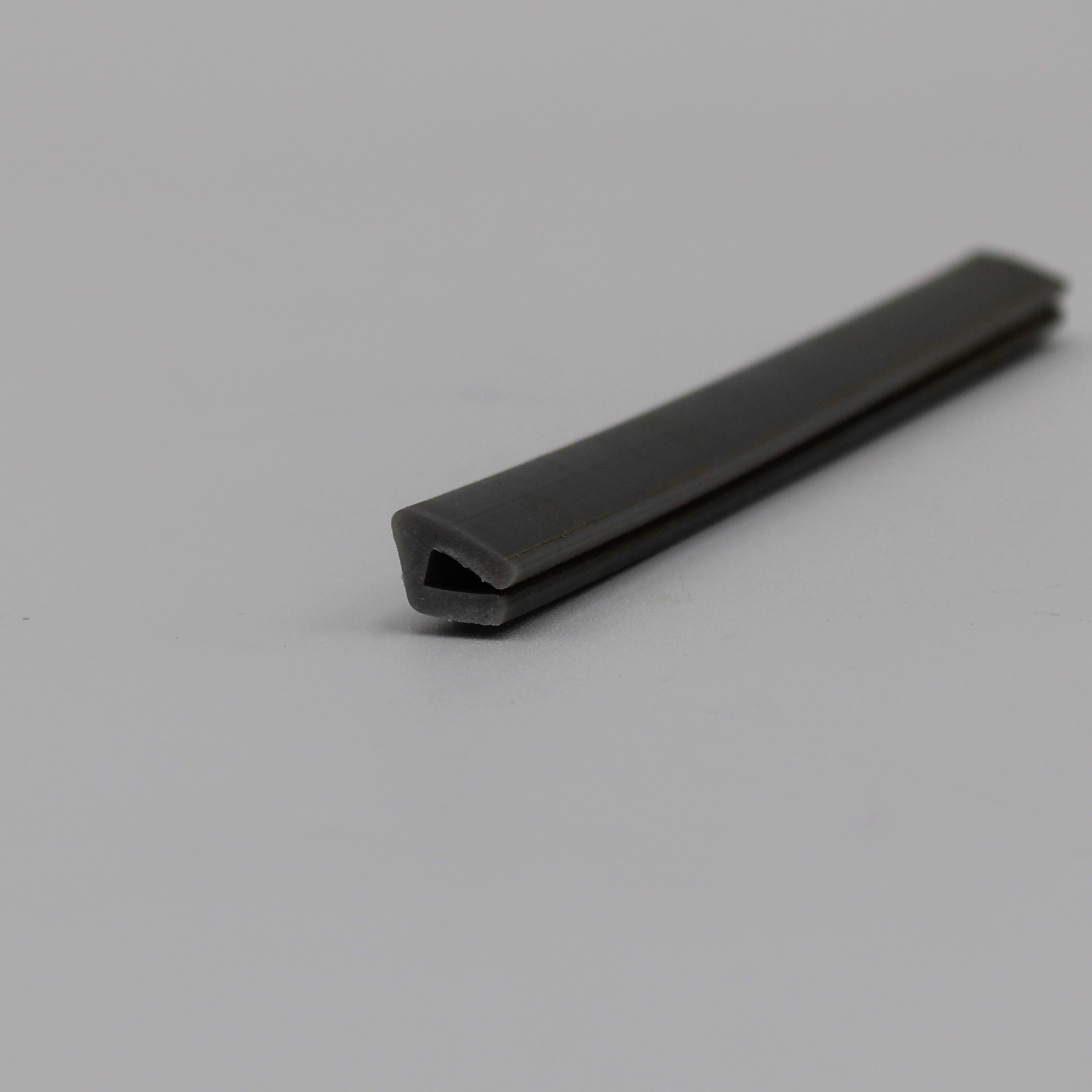

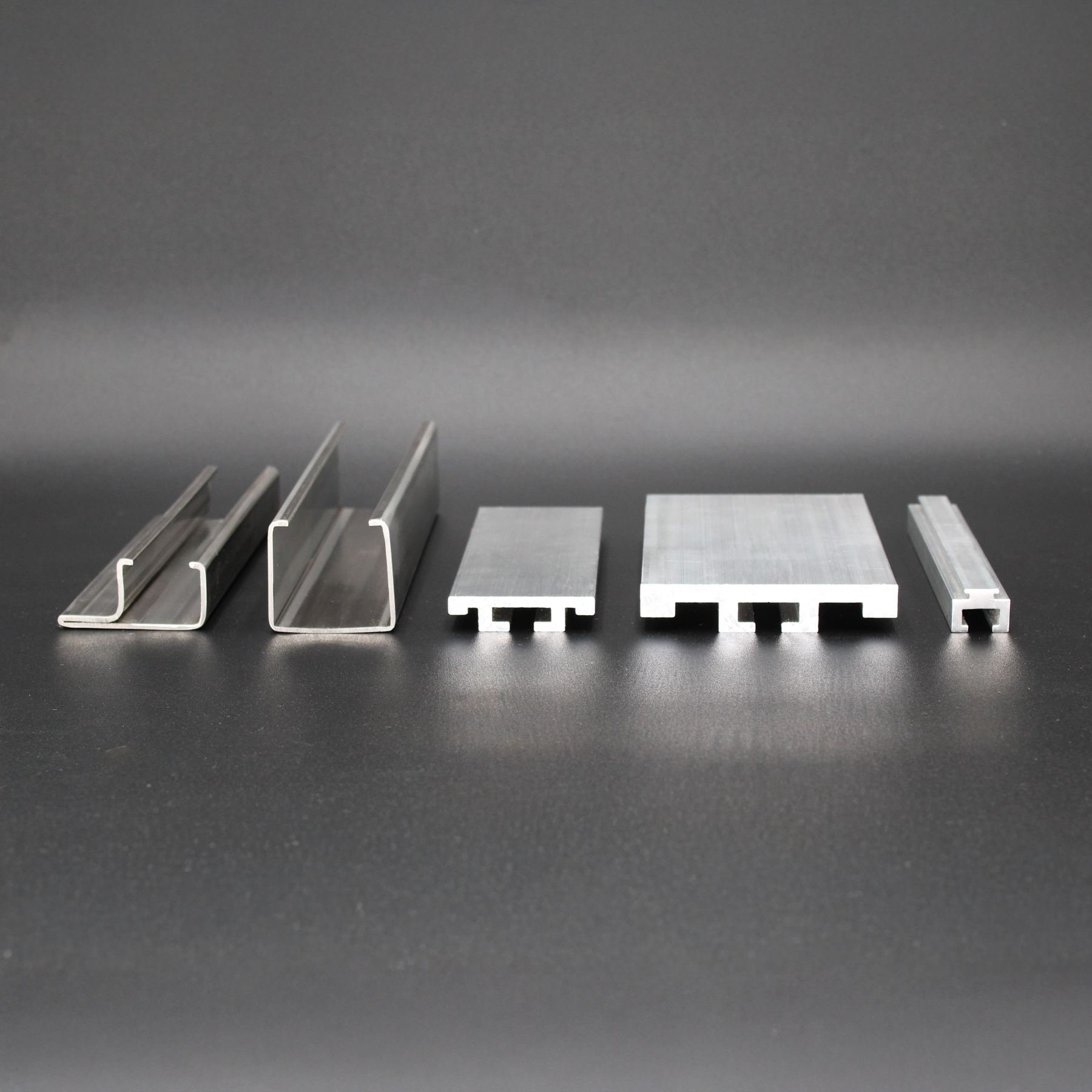

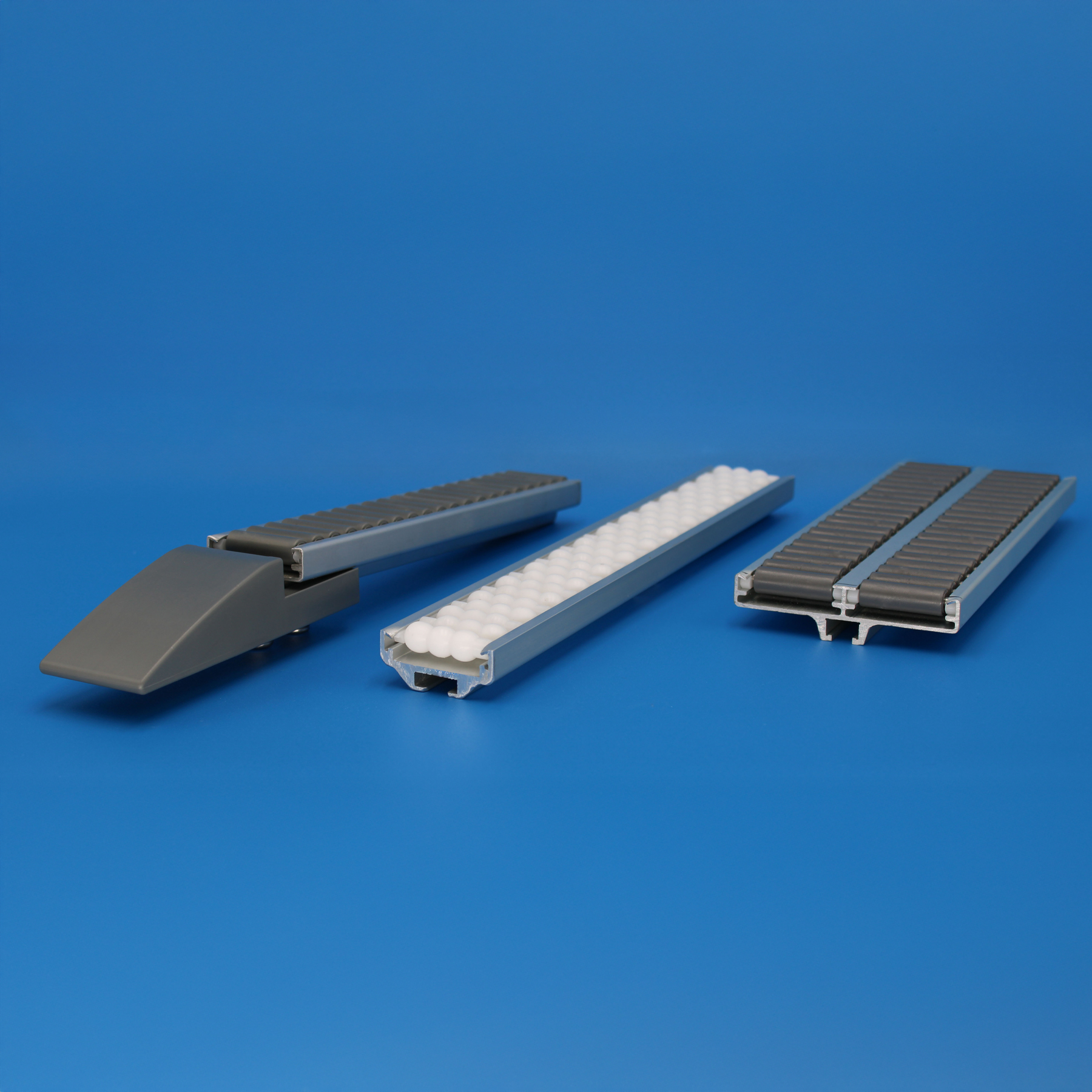

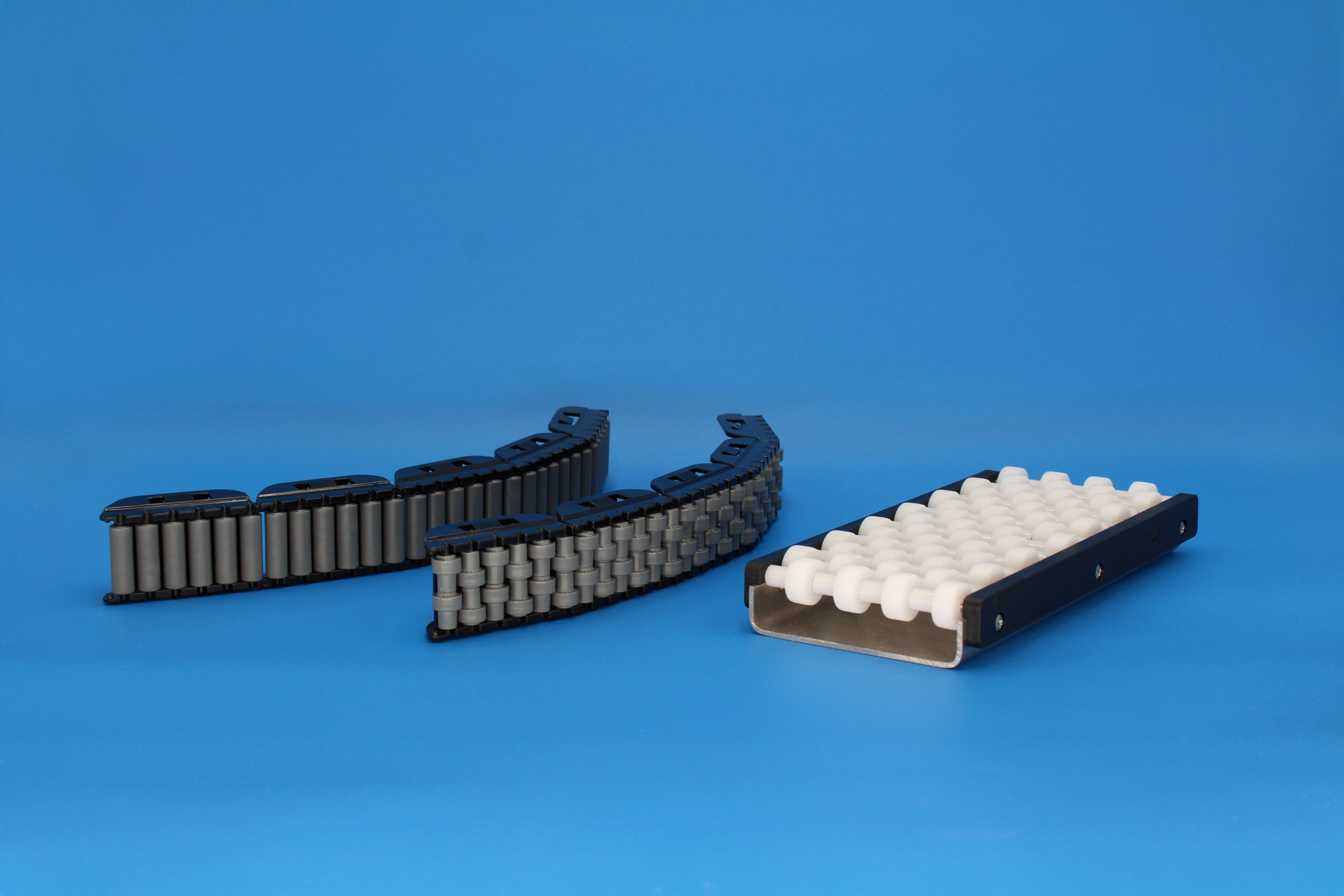

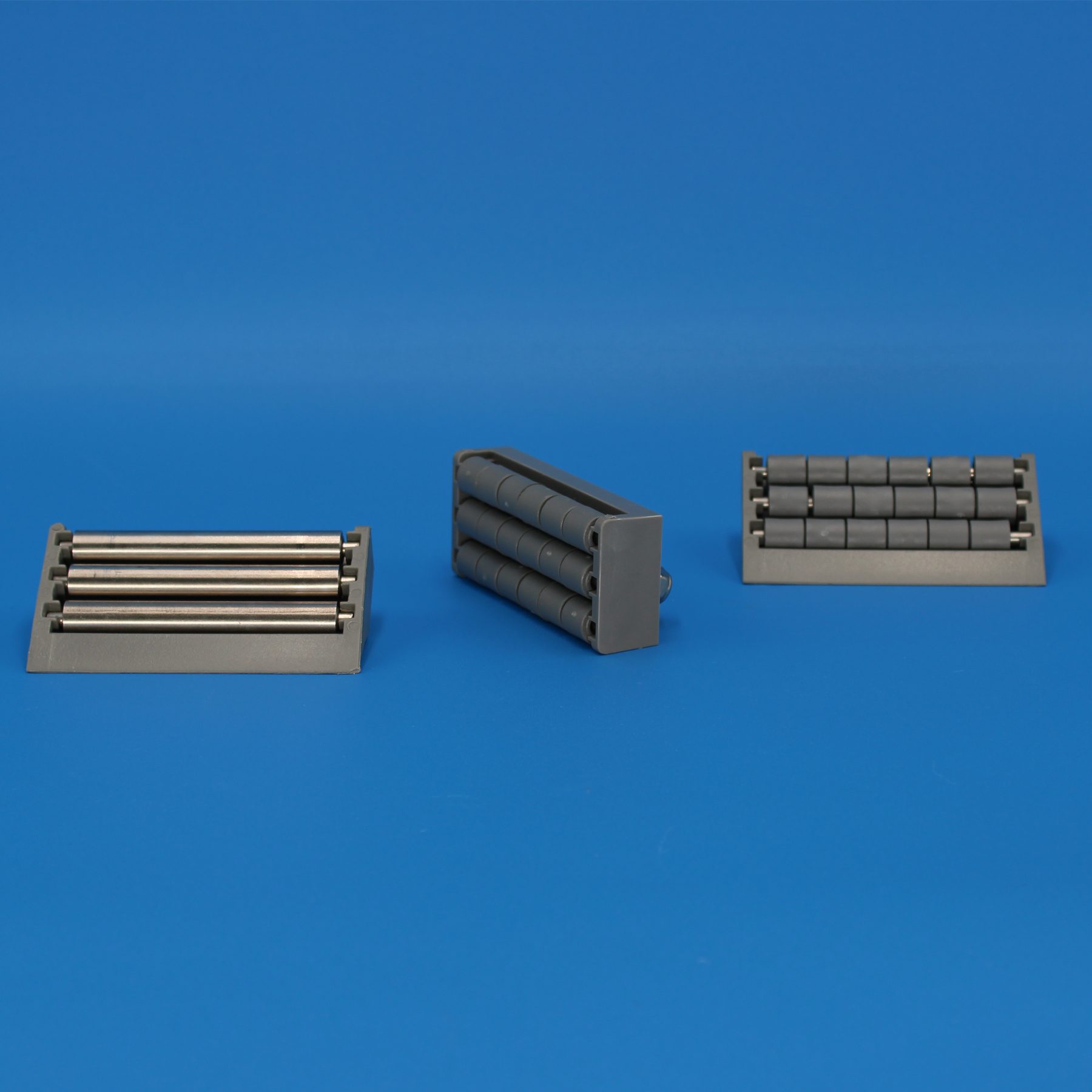

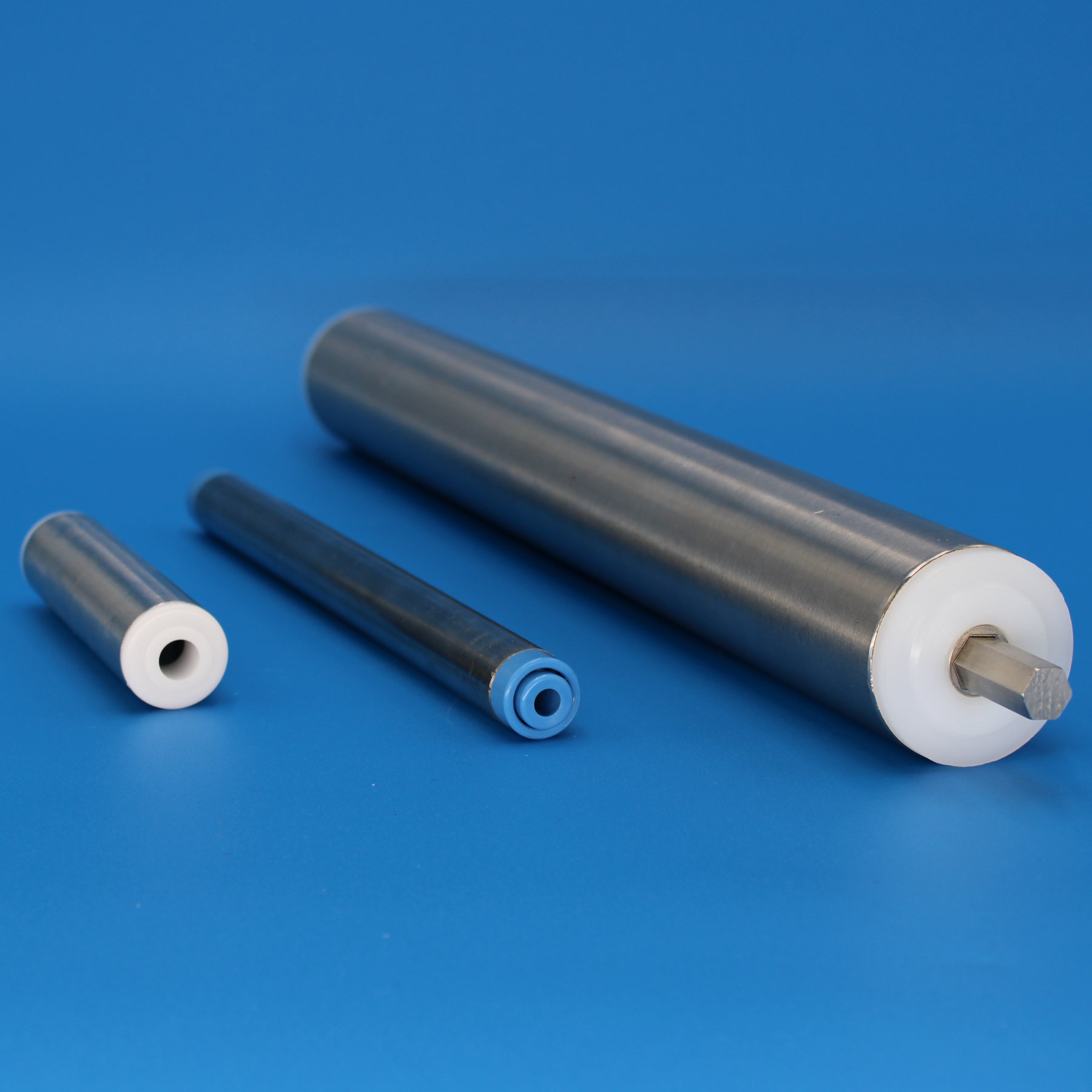

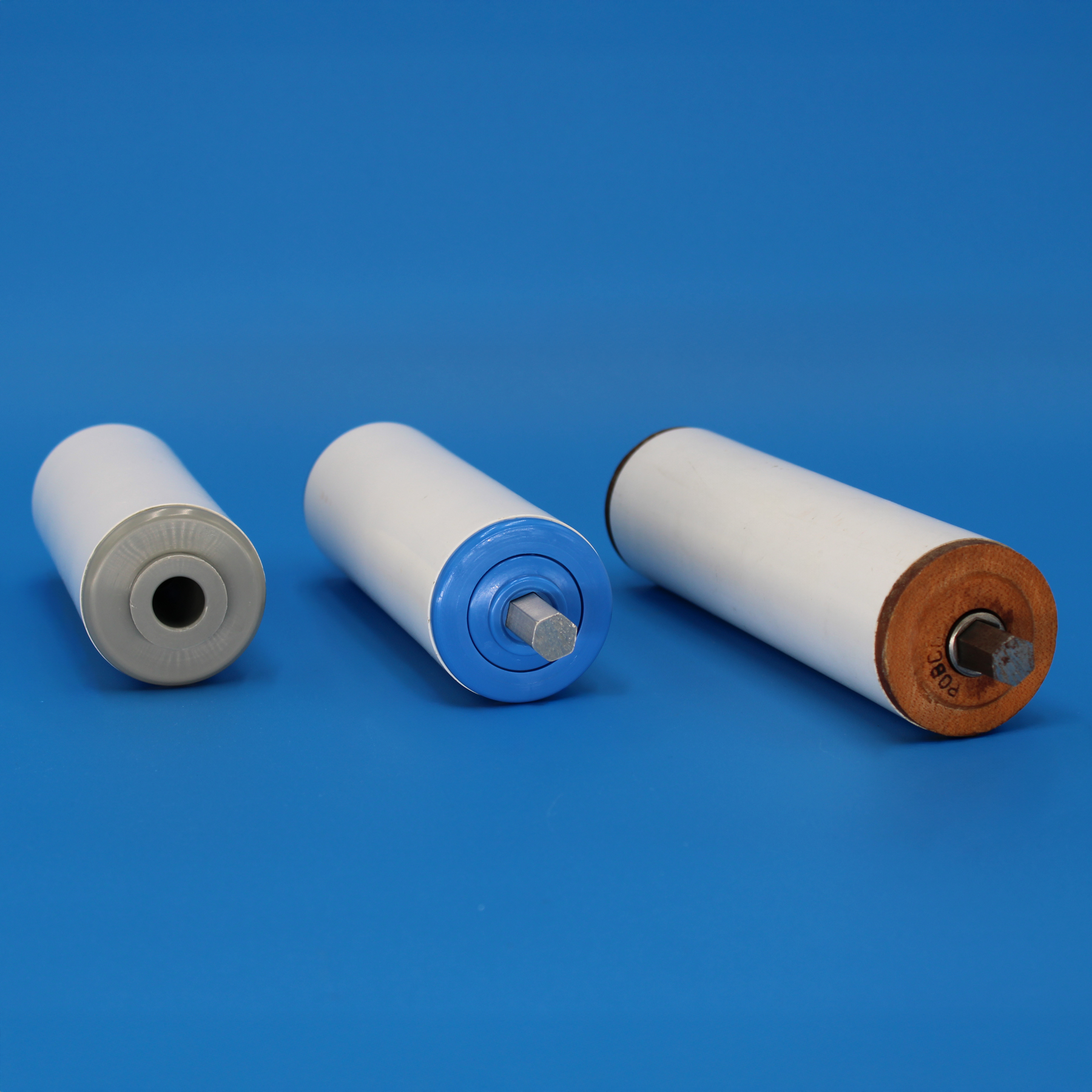

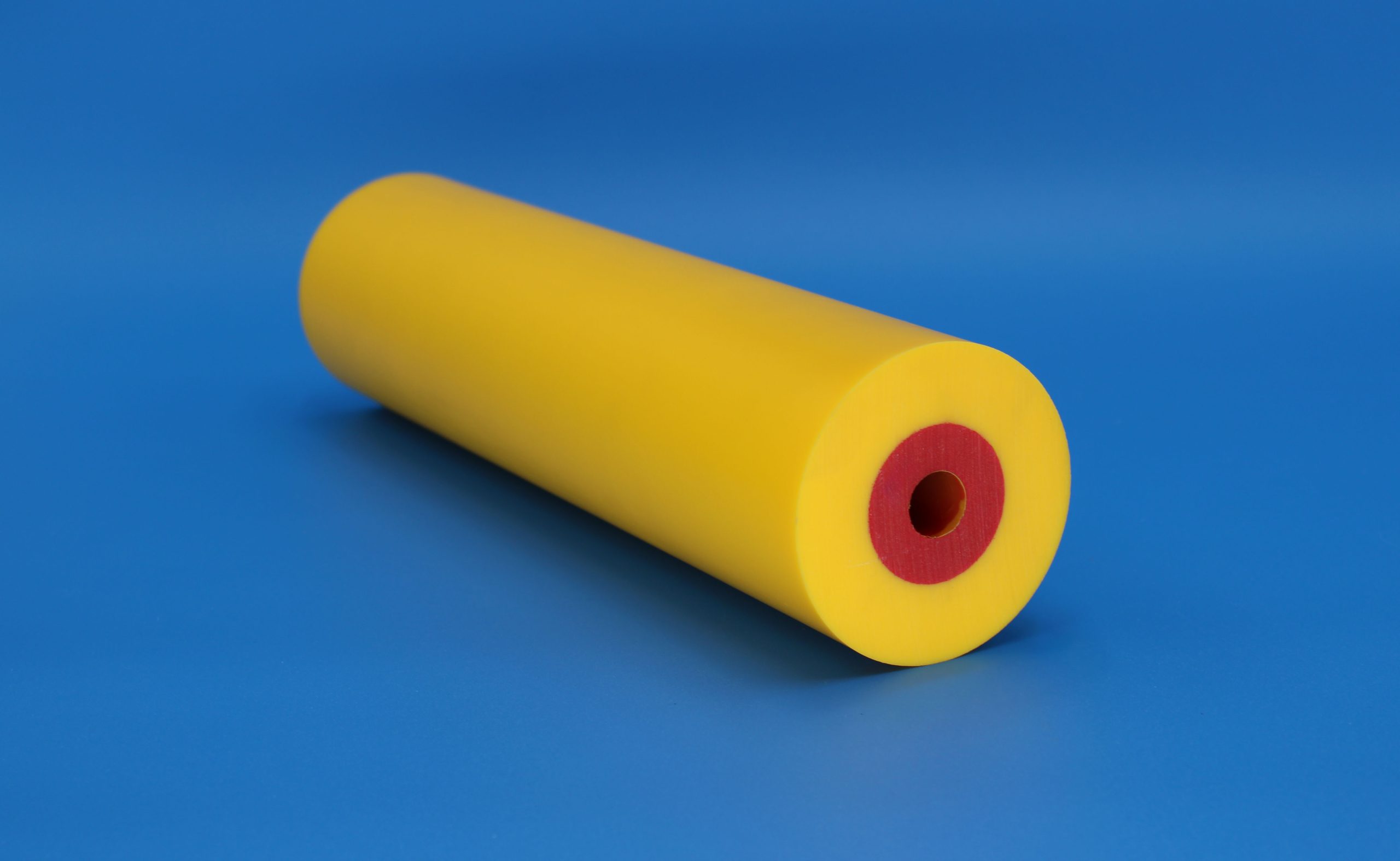

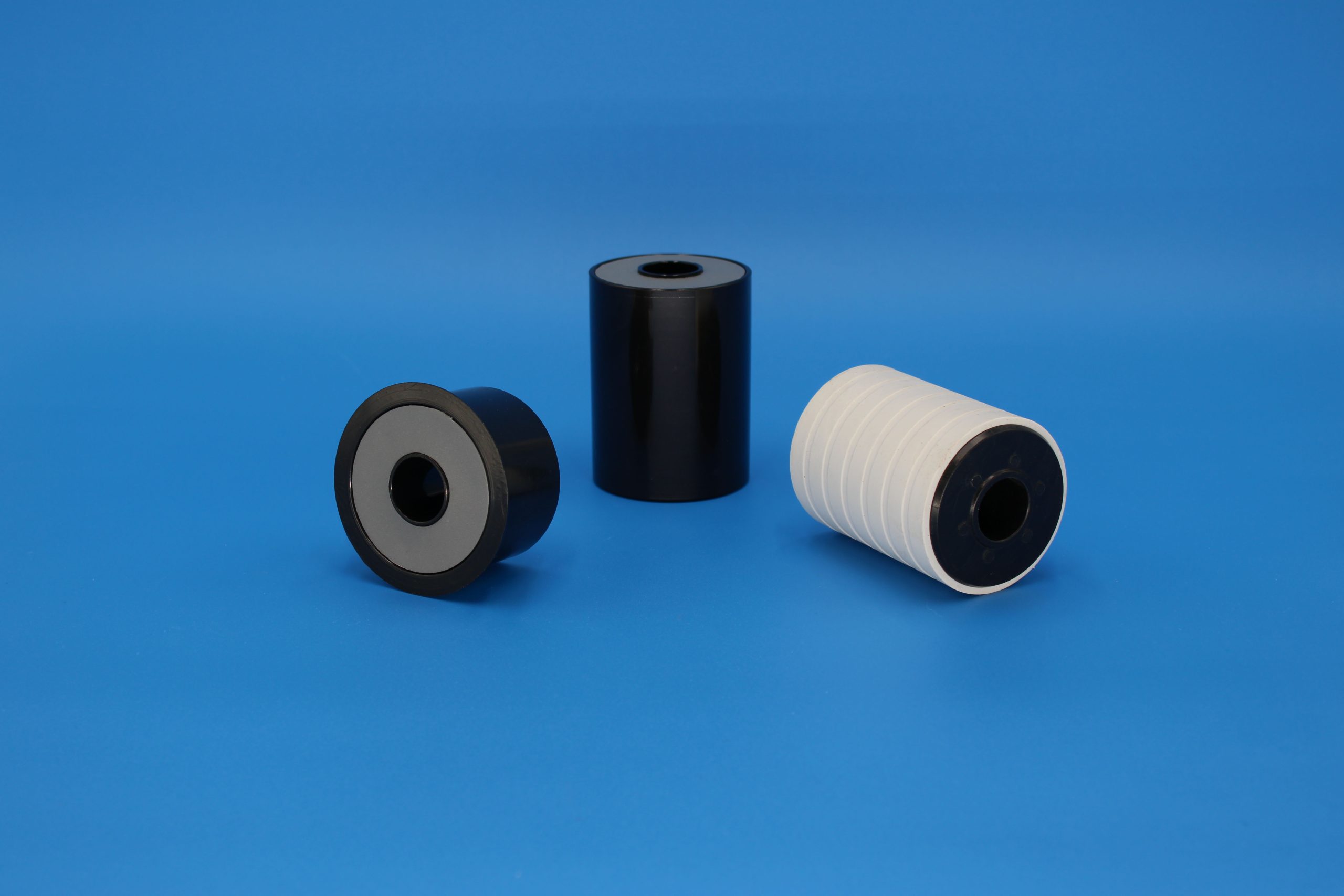

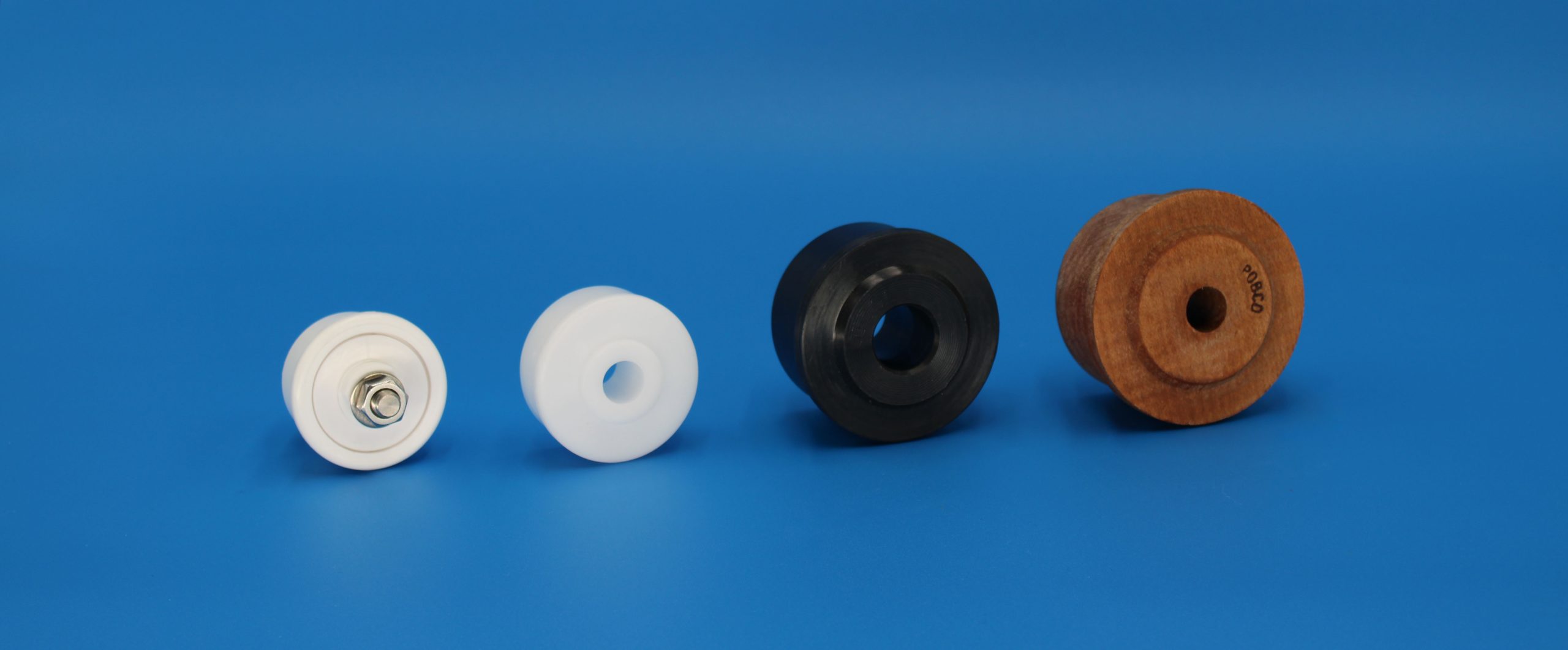

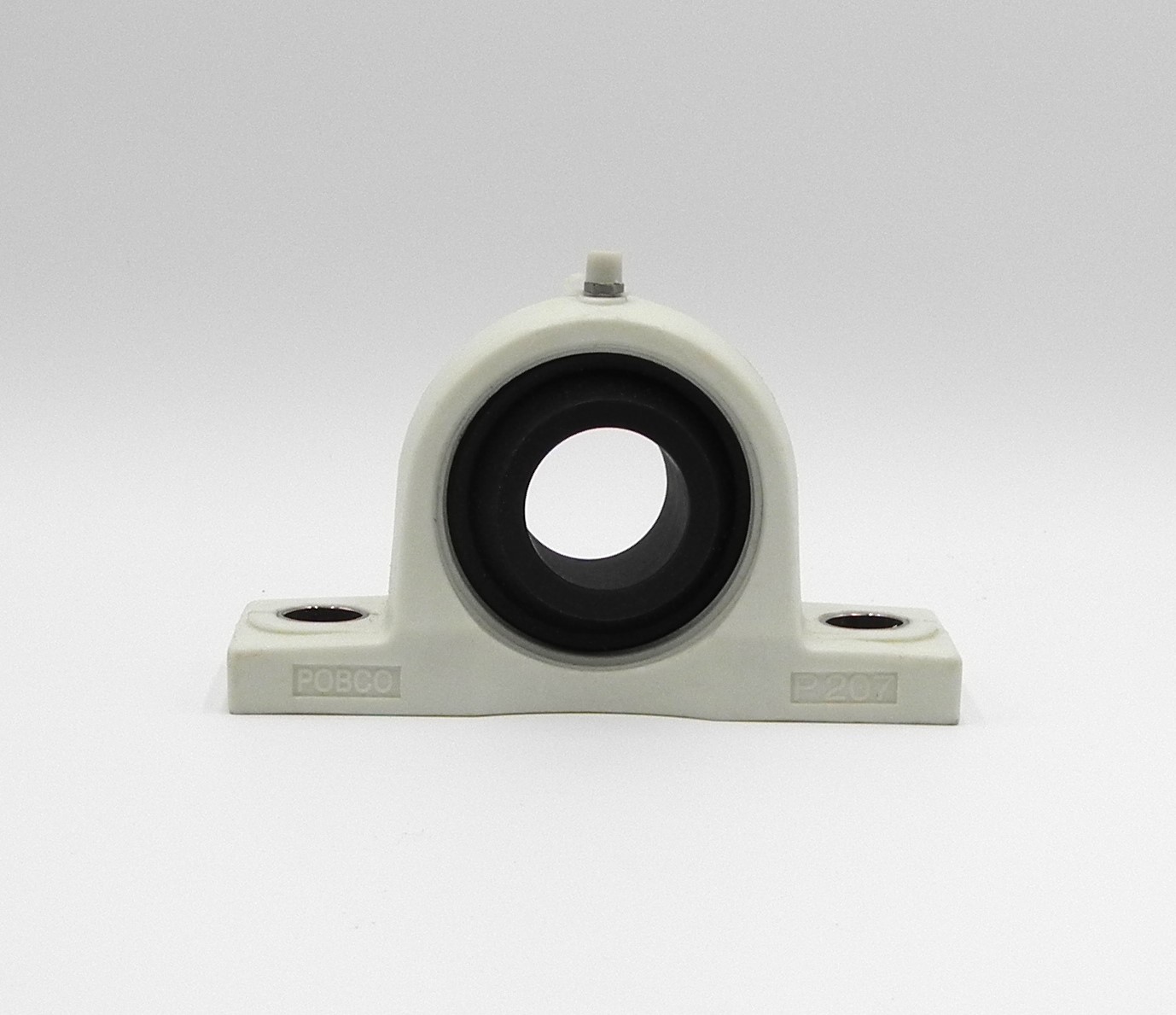

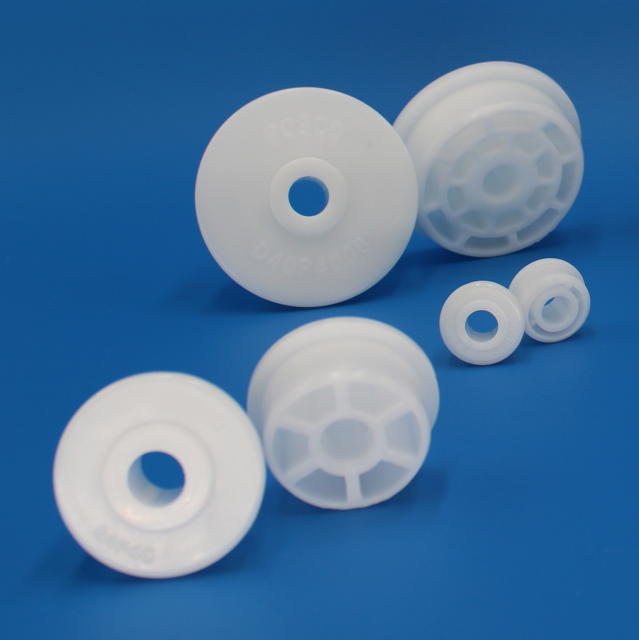

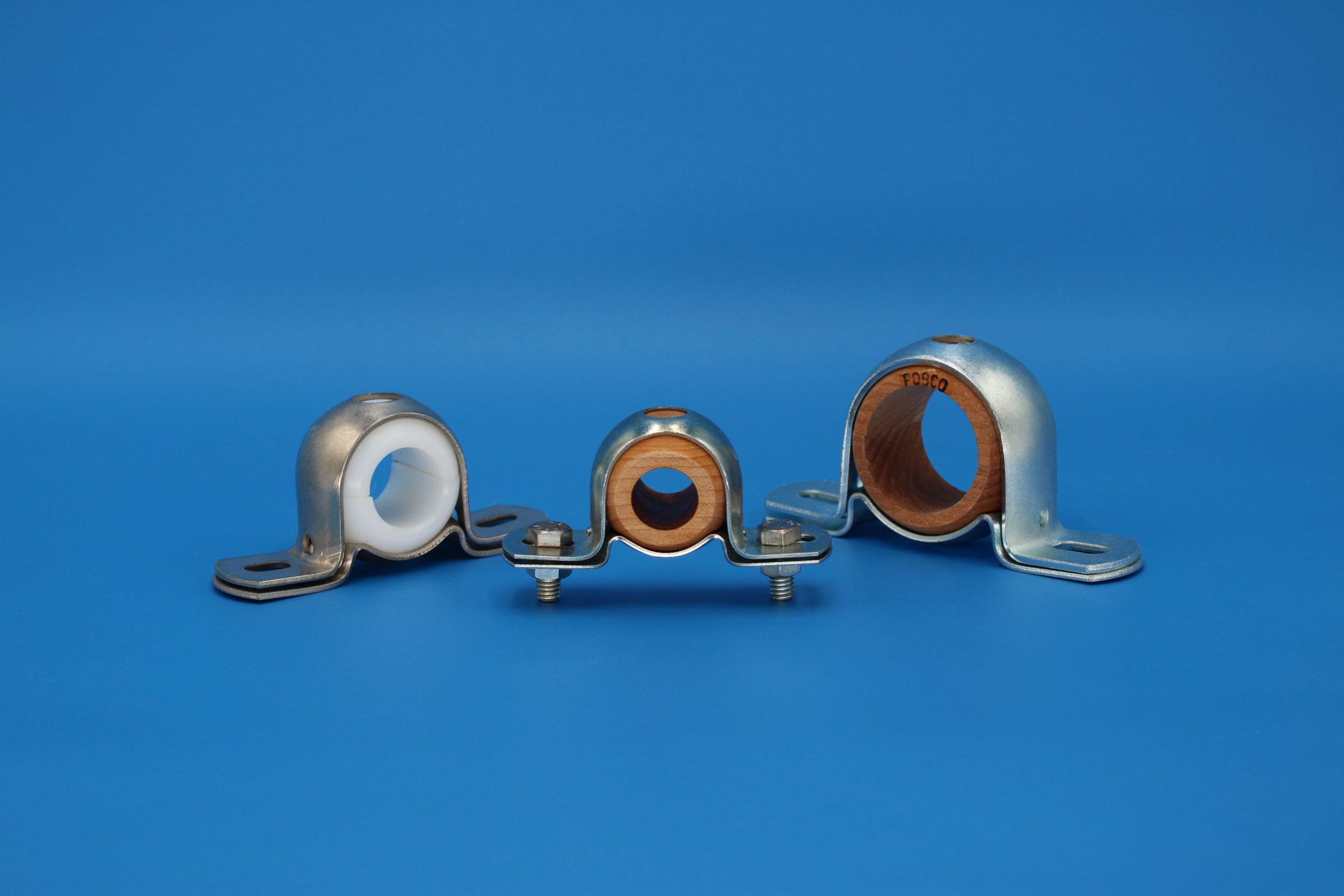

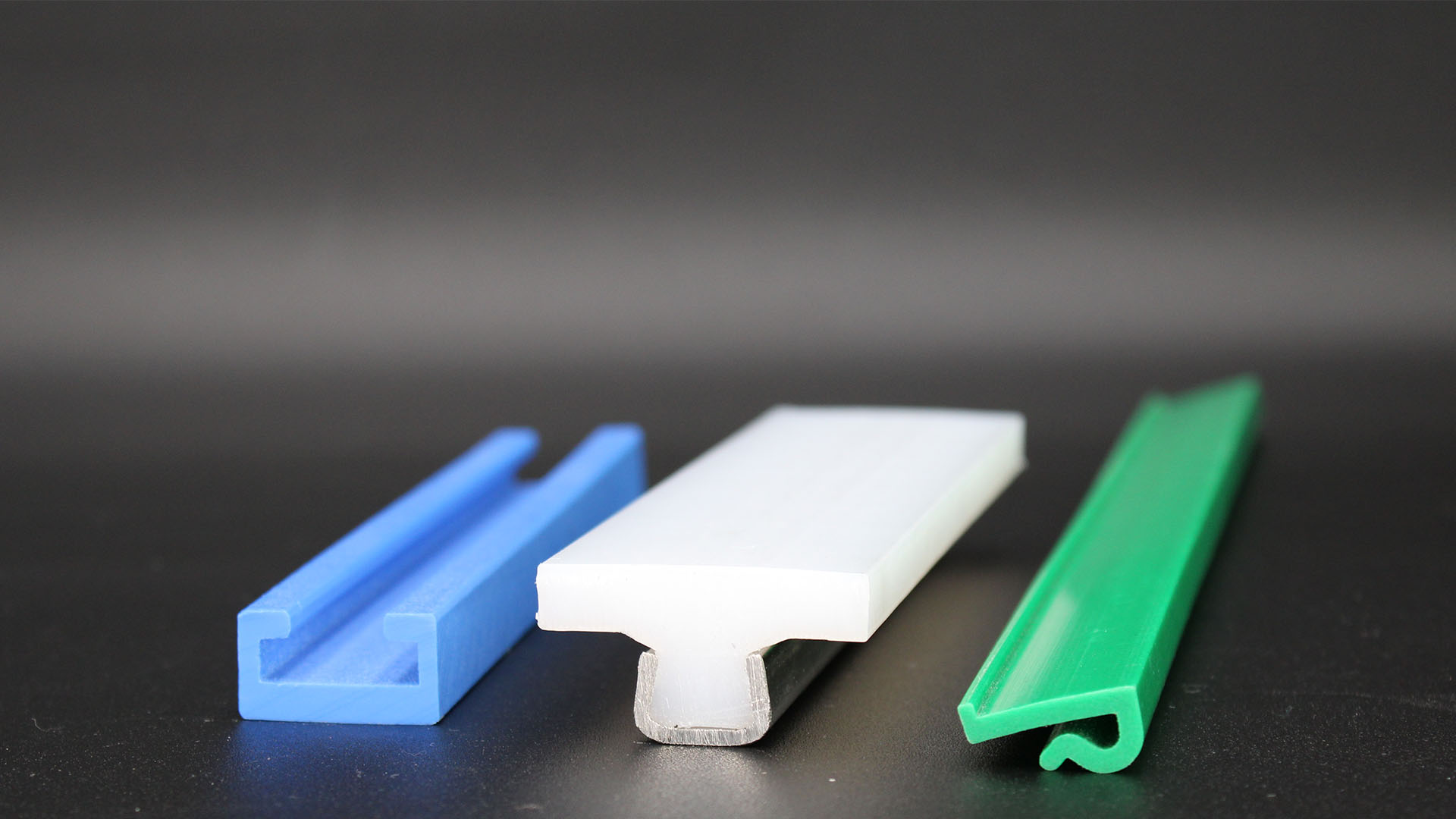

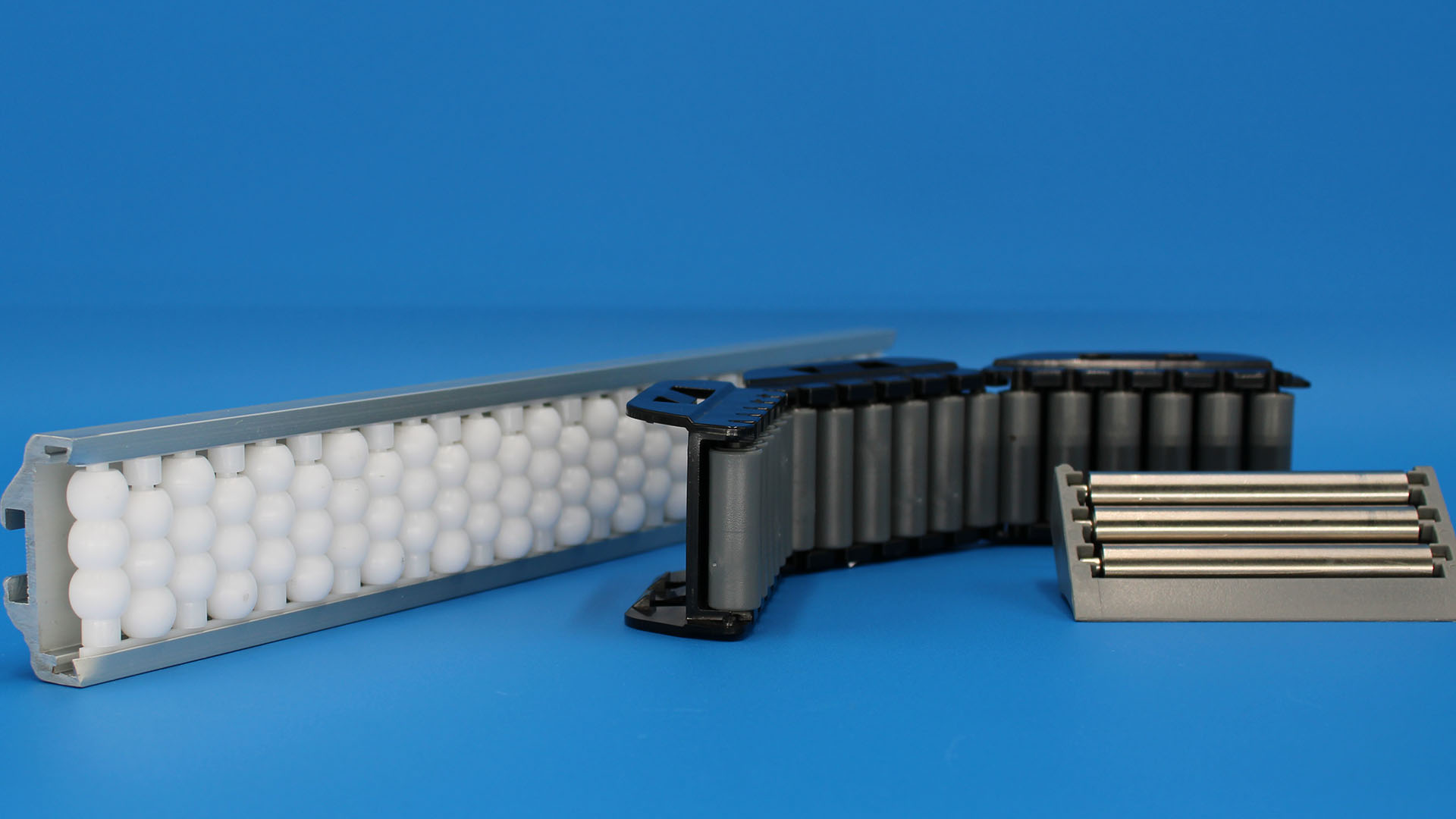

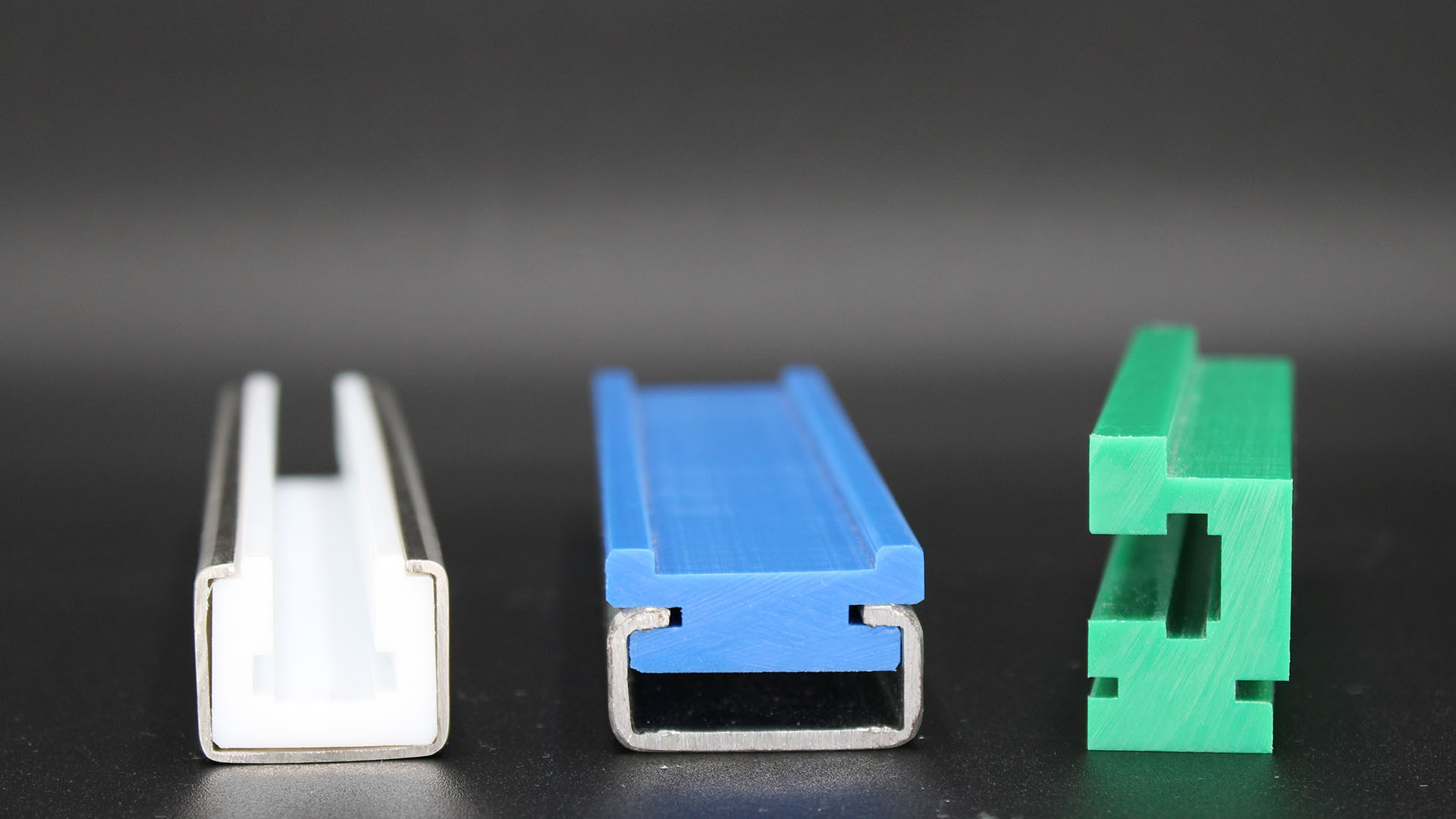

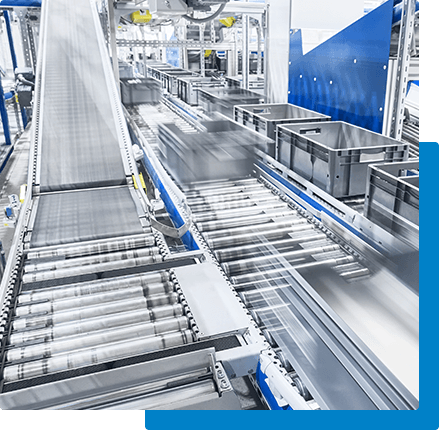

POBCO leads the industry in manufacturing and distributing conveyor components. Our customers rely on us for expert sales support, readily available inventory, competitive pricing, and prompt delivery. We’re committed to solving problems, building strong relationships, and delivering the reliability that earns lasting loyalty.

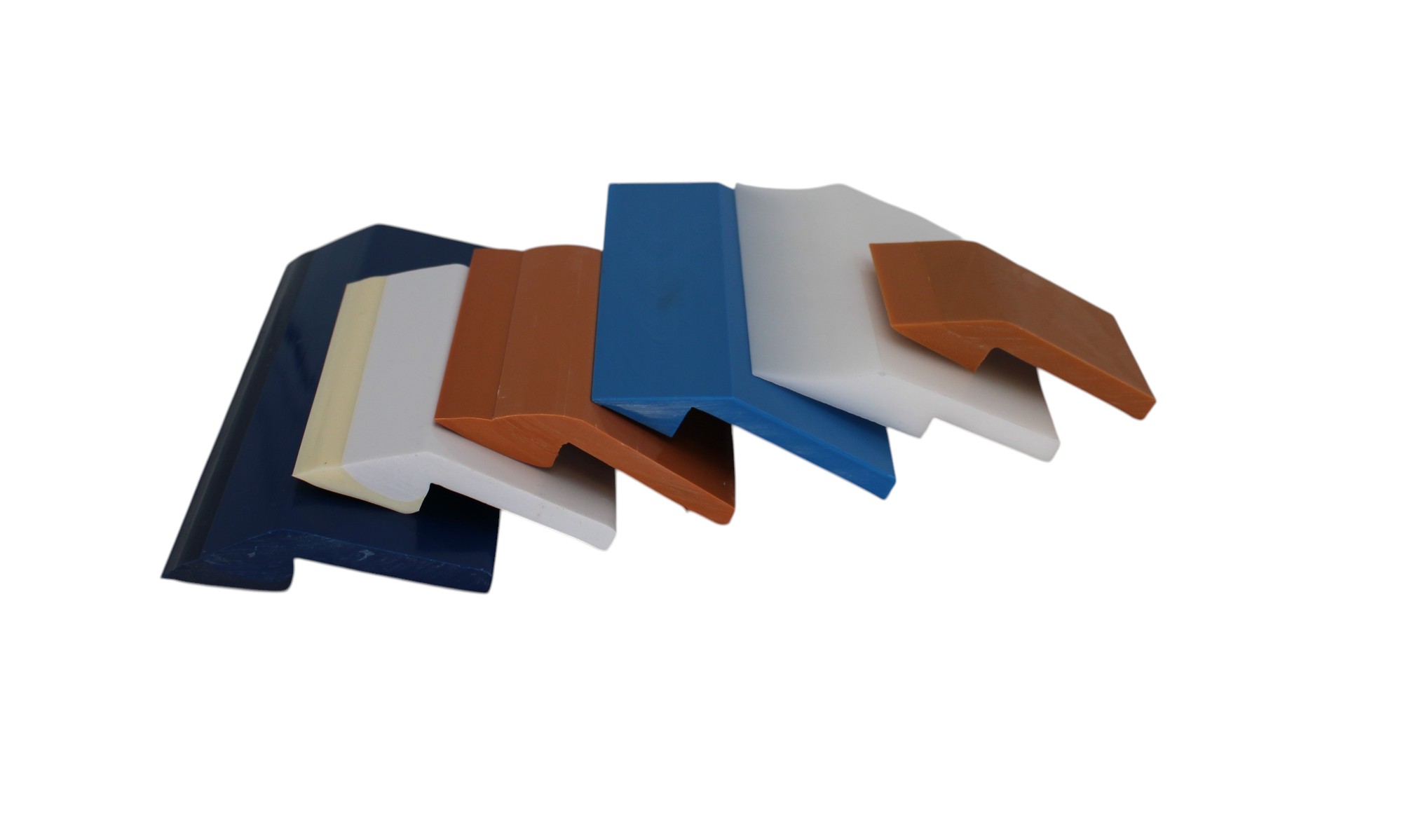

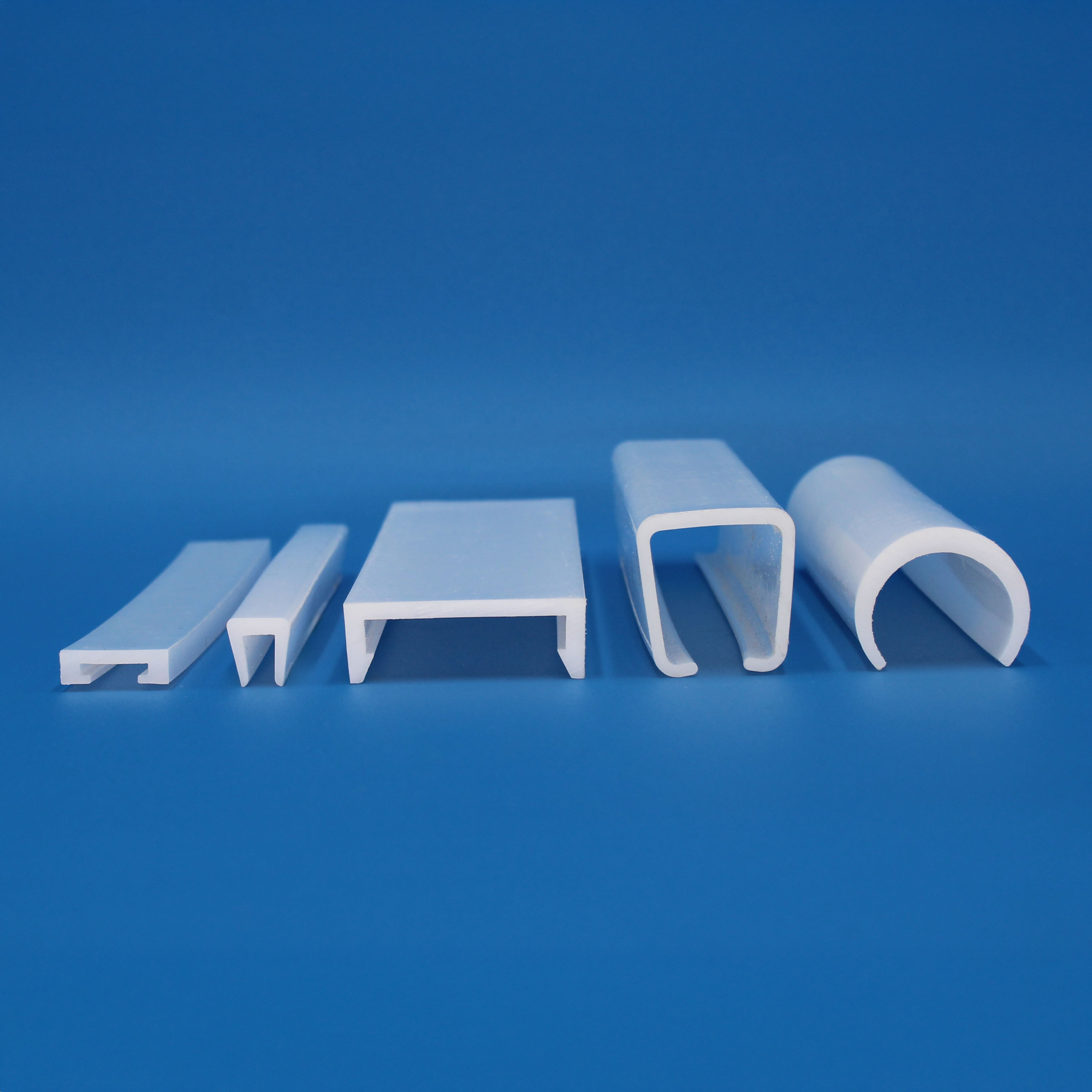

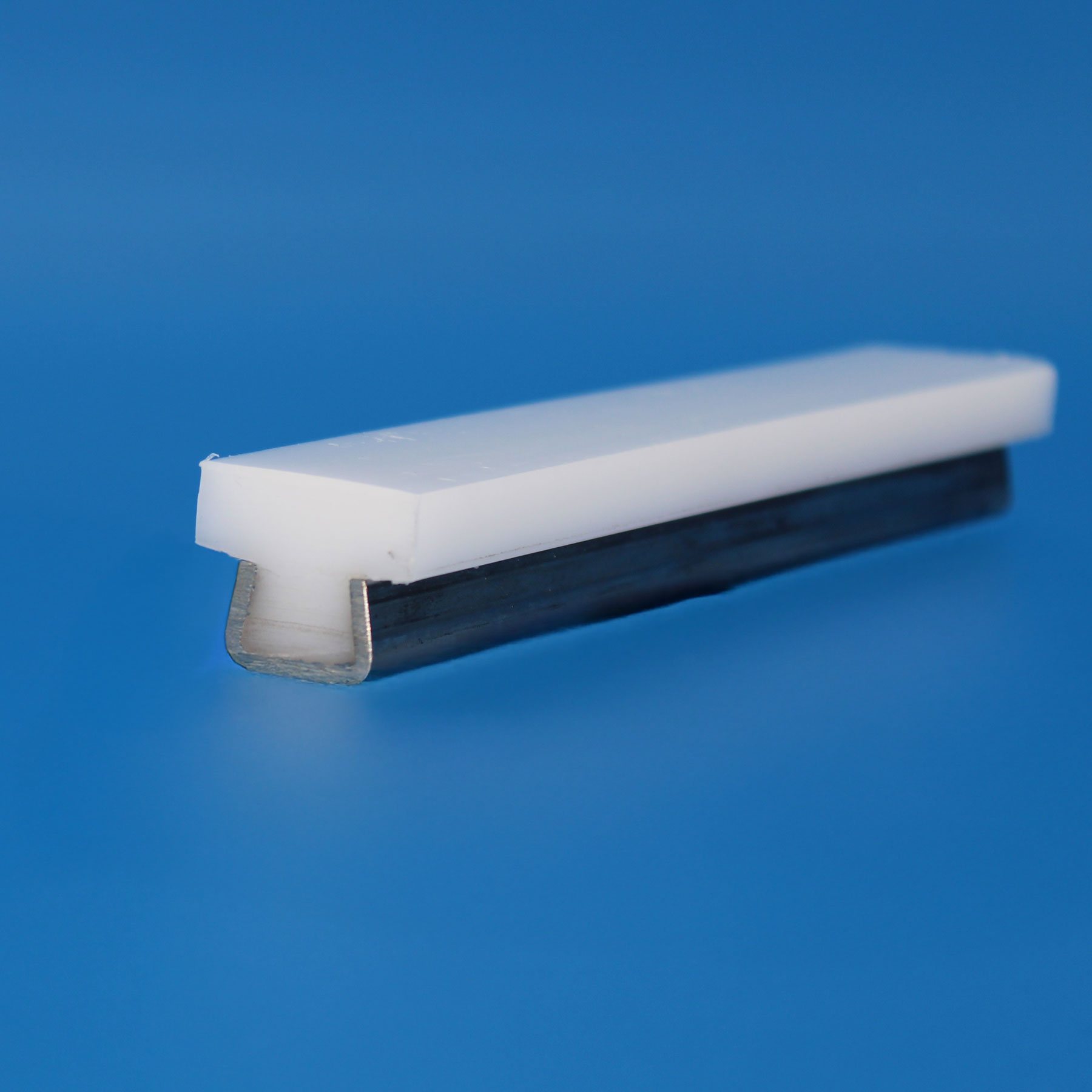

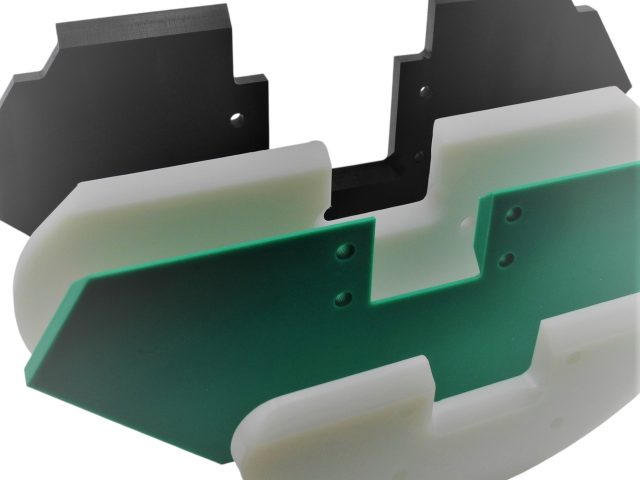

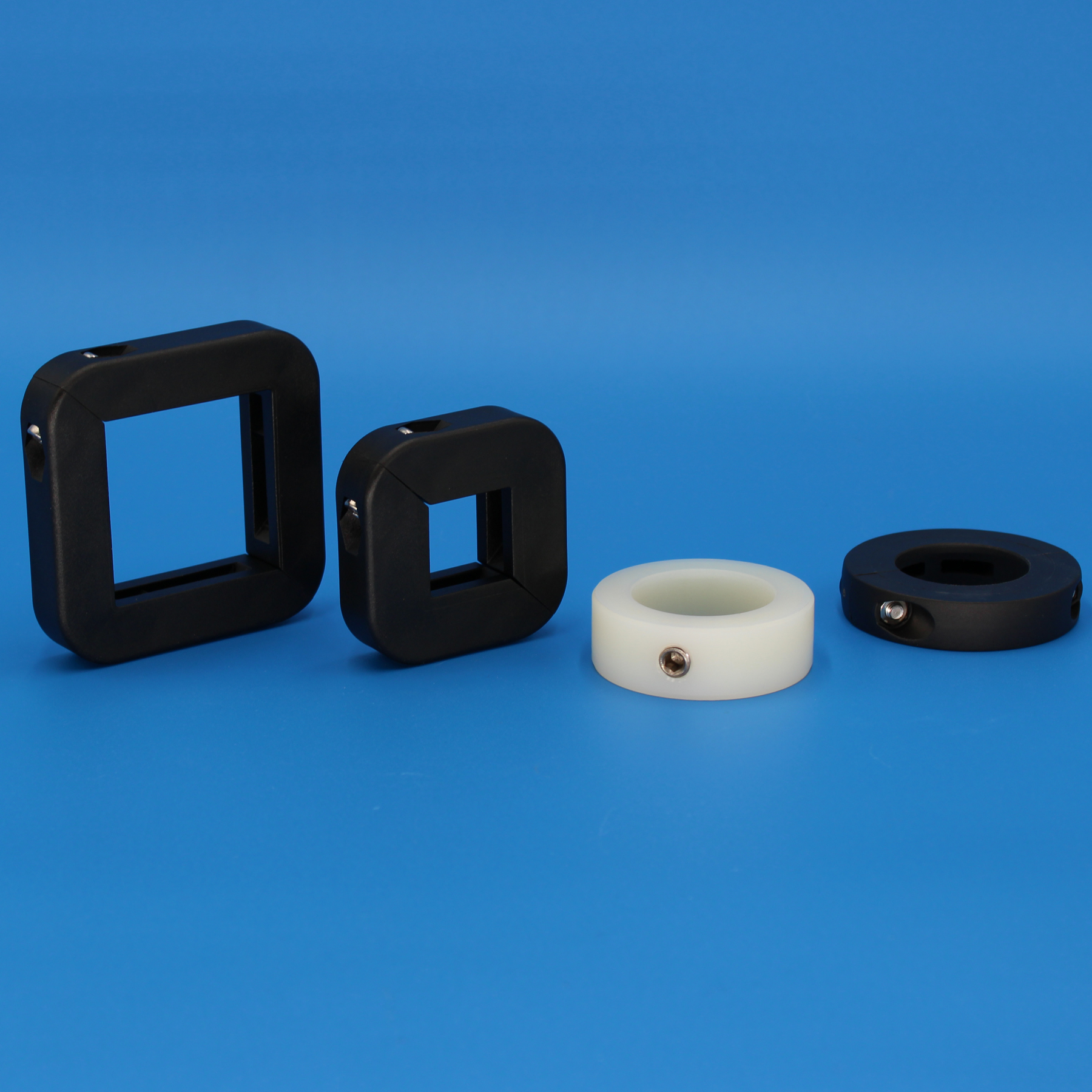

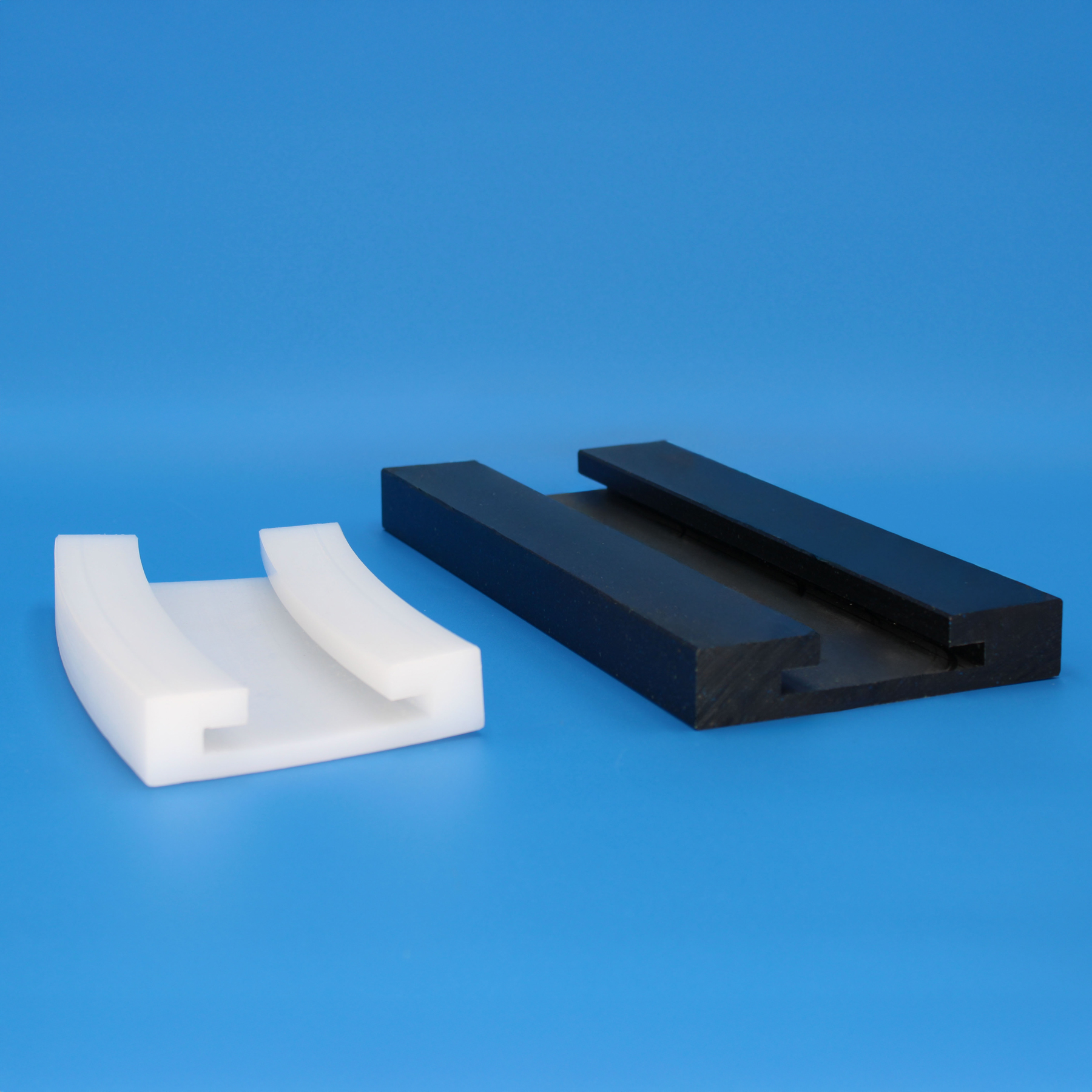

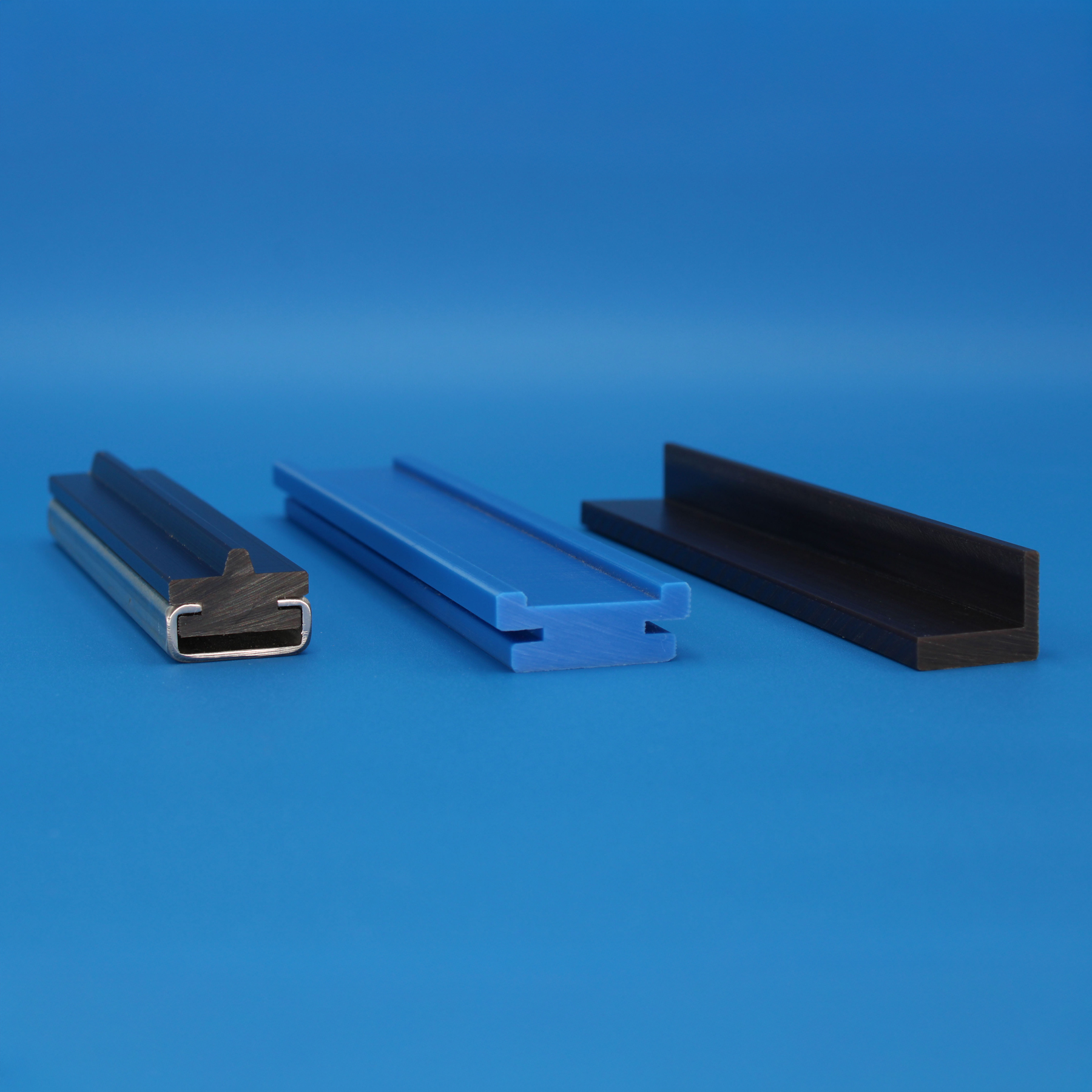

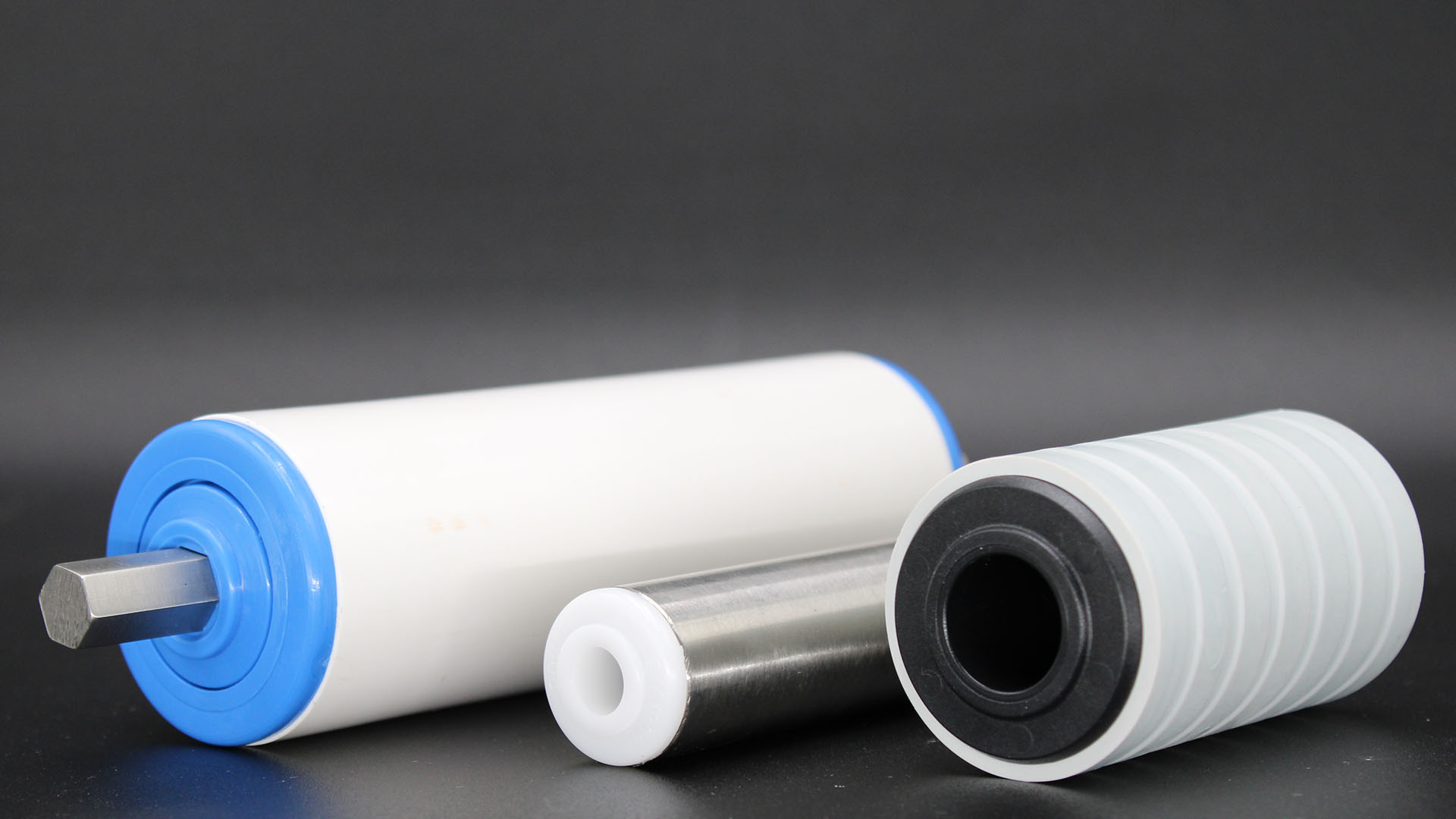

Featured Product Category: PET Neck Guides

About POBCO Inc.

Celebrating 90+ years as a successful manufacturing business in Worcester, MA. POBCO Inc. remains a 4th generation, family-owned business with a growing employee family. Current ownership and employees emulate the work ethic and dedication of our predecessors. The excellence of our current and past personnel is the backbone of POBCO’s Inc. globally respected brand.

POBCO Inc. humbly requests the opportunity to work with you on your upcoming conveyor components projects.